Enhance Smart Manufacturing Networks

Upgrade Traditional Infrastructure

Smooth transition to an automated network system for a smart industrial application

IIoT Capability

Enable a complete connected network for efficient operation and reduce onsite personnel with full remote central network management

Comply with Industrial

Network Protocol

Utilize major industrial Ethernet protocol including ModBus TCP, EtherCAT, and TSN

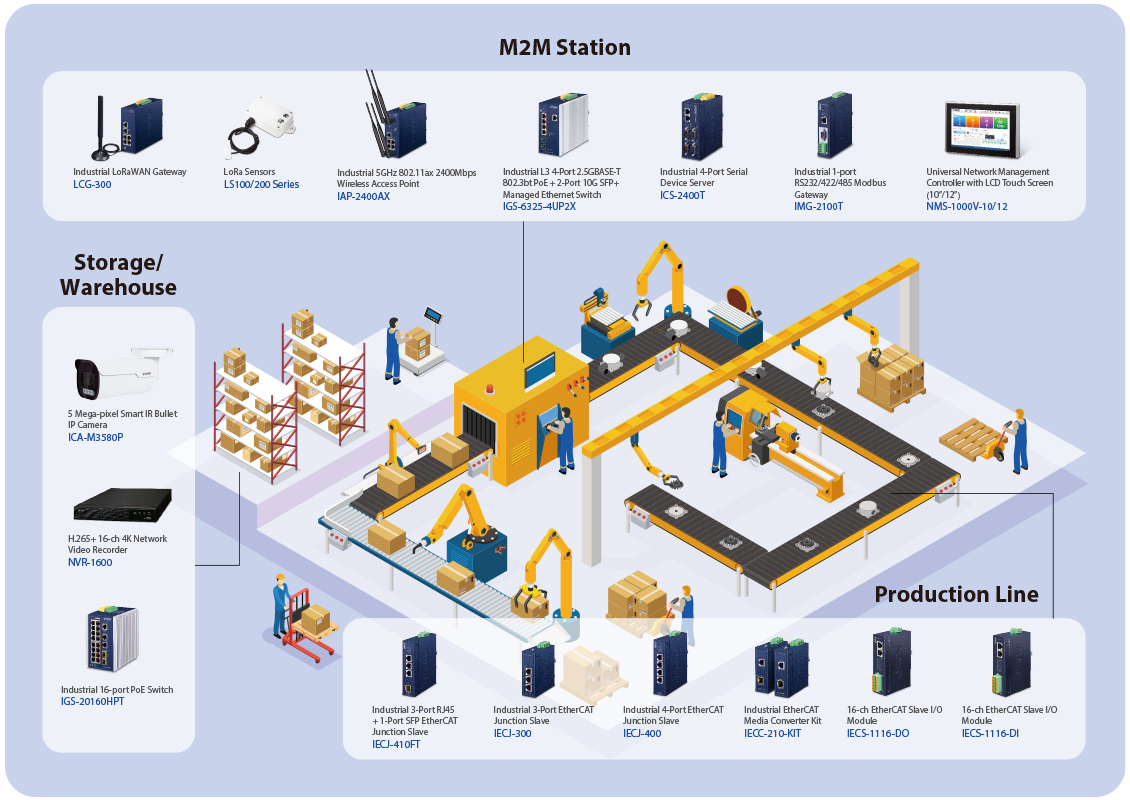

Accelerate Smart Manufacturing Network for Industrial Digitalization

Transforming a traditional production with smart manufacturing technology is always a challenge with existing digital networks, M2M communication and business strategy regarding investment in IIoT. We all know the importance of digital transformation, but how to realize it with the customer’s maximum benefit is the mission of PLANET.

For smart manufacturing, timing and precision are highly crucial. Verticals, such as manufacturing plants, production areas, factories, supply chains and other types of industrial applications, have an advanced network infrastructure that can greatly enhance the overall operational efficiency of their facilities.

What Network Conditions are Needed for Smart Manufacturing

What Network Conditions are Needed for Smart Manufacturing

- Timely and precise: Every millisecond is crucial to ensure the operation is functioning properly

- Transmission of high-volume data: Large data transmission is required for smart manufacturing facilities

- Adaptable and scalable network: Able to provide efficient network transmission in smart manufacturing network of any size.

What is the Solution?

When it comes to fast and precise transmission for factory automation, PLANET provides a complete smart manufacturing network solution to upgrade existing networks with IIoT functionality.

PLANET smart manufacturing application is one of its many Industrial Ethernet Solutions that provide highly reliable and smart solutions to ensure continuous and efficient operation for the IIoT environment. The Industrial Ethernet upgrades traditional, proprietary factory-floor networks to a high-performance and scalable architecture. PLANET provides a complete product portfolio that is compliant with major IE protocols such as EtherCAT, TSN, Modbus TCP and EN50155 for information level, control level, and device level in the Industrial Ethernet network.

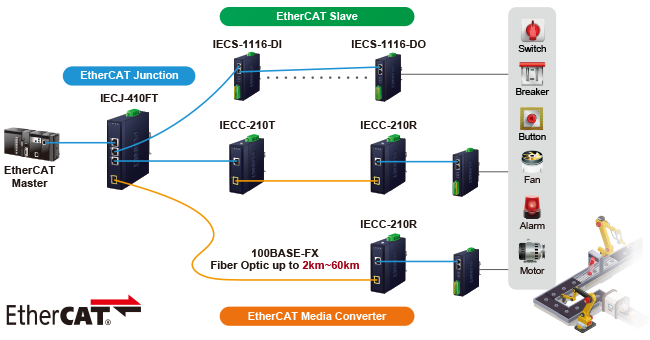

◆ Automation with EtherCAT

Utilizing PLANET’s expertise in developing innovative networking for industrial applications, Slave I/O Module, Junction and Media Converter with EtherCAT functionality are available to enable high-speed communication and synchronization between industrial devices including sensors, switches, alarms, etc.

- Utilize EtherCAT protocol

- Expand topology options: Star, Tree, Daisy, Bus

- Synchronization for precision in data communication

- Extend the reach with EtherCAT media converters up to 60km

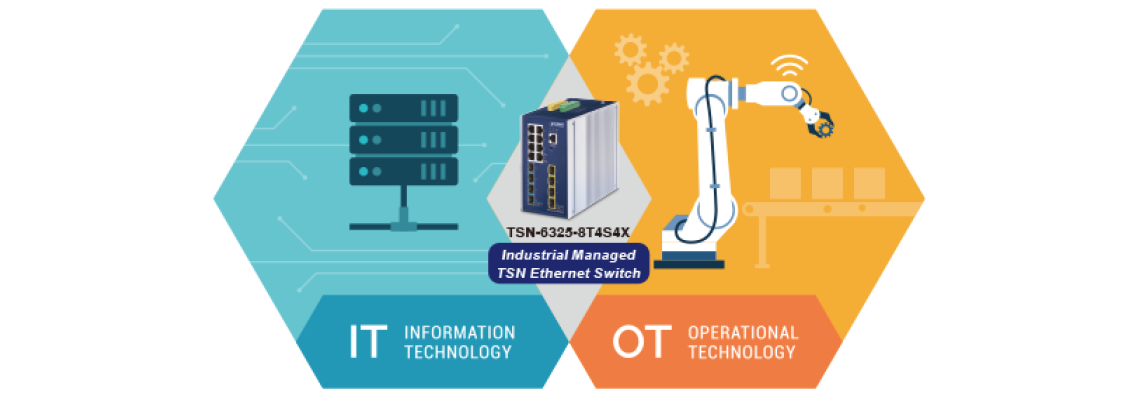

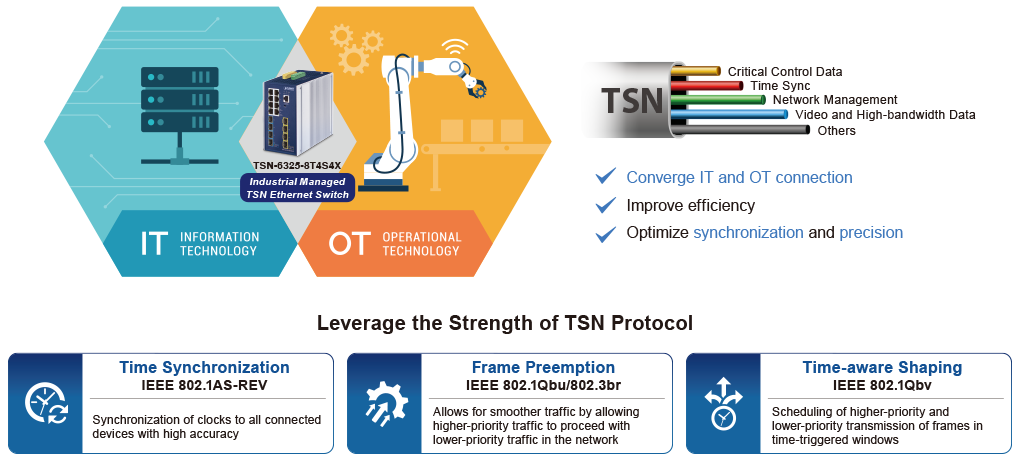

◆ Precision with Time Sensitive Networking (TSN)

Streamline critical and non-critical data into one network transmission to enable efficient and precise data communication. This can significantly optimize the network that transmits data for automation, and eliminate the need to prioritize and delay certain data.

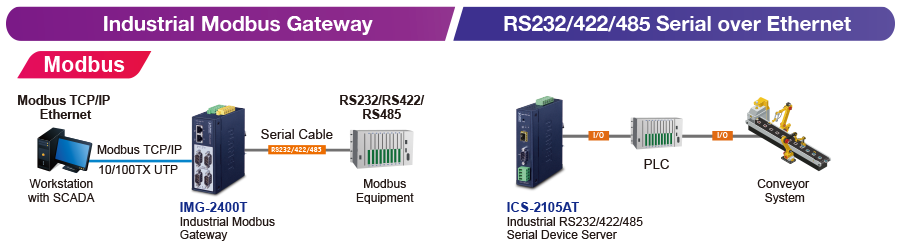

◆ Bridging the Gap Between Ethernet and Serial Ports

Implementing automation features to enable a smart manufacturing network can be efficiently done with your existing infrastructure. By utilizing PLANET’s Modbus Gateway and Serial Device Server, RS232/422/485 equipment can easily connect with new Ethernet operations.

- A perfect way to connect existing Modbus network with serial ports to IP Industrial Ethernet

- No need to replace serial devices, helping to extend the usage of existing equipment

- Conversion bridge between the RS233/422/485 equipment with the Modbus RTU/ASCII Protocol

- Scalable network, easily integrated with SCADA/HMI system and other data acquisition systems

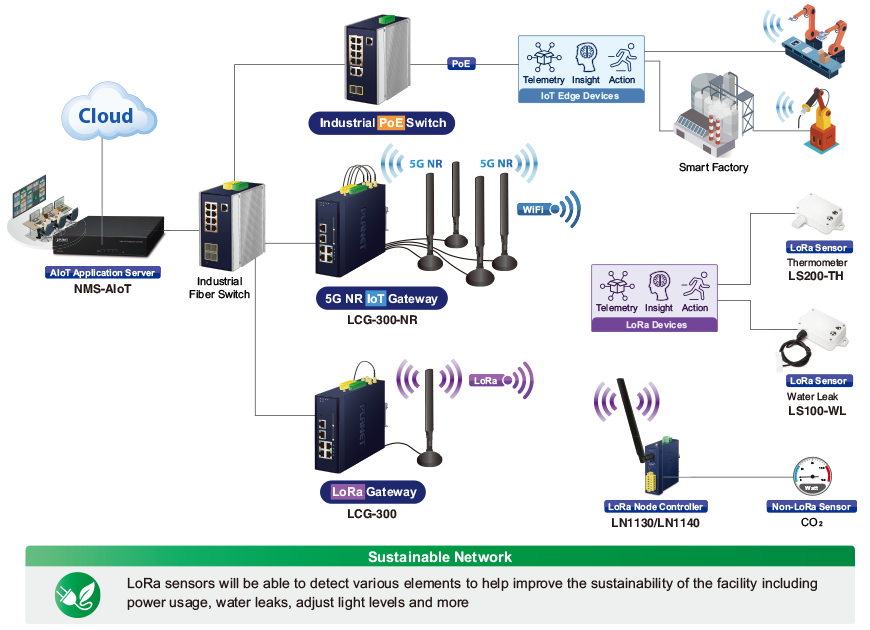

◆ Enable Intuitive AIoT Network with LoRaWAN Technology

PLANET provides a full suite of LoRa technology enabled devices to fully take advantage of the long range and low power nature of LoRa. By combining LoRa sensors, gateways and management system, the network will be able to easily collect big data information to be utilized in the AIoT network.

- AIoT Application Server (NMS-AIoT)

Intuitive interface and complete analytical information of all the connected LoRa devices and network switches - Industrial LoRaWAN Gateway (LCG-300/LCG-300-NR/LCG-300W)

Efficient and reliable collection of data from LoRa sensors to be used in Big Data network - LoRa Sensors (LS100/LS200 Series)

A collection of sensor variety to transmit data directly to the LoRaWAN Gateway: temperature (product, indoor, machine, refrigerator), water leak, light level, power current meter, occupancy, door/window contact - LoRa Node Controller (LN1130/LN1140)

Non-LoRa sensors can be converted to be used in the LoRa IP Network

Technology Implementation

Will all the network protocol for EtherCAT, TSN, Modbus and Serial over Ethernet be able to operate within the same network?

PLANET network devices are able to work together

no matter the protocol. Admin will have the ability to remotely manage

and monitor all the connected devices from each protocol to ensure the

network is operating properly and efficiently.

Can the network reach be expanded if the facility sees an expansion?

The EtherCAT network is an example where the

utilization of PLANET EtherCAT Junction Slave, Media Converter and Slave

Modules can easily extend not only the reach of the network with fiber

optic connection but also use different topology base on the scale of

the network facility.

A smart manufacturing network will

require strong protection against potential threats, how will the

solution implement cybersecurity?

PLANET continuously updates and implements the

latest cybersecurity protection for mission-critical networks such as

the inclusion of SSHv2 and TLSv1.2 protocols for advanced threats.